Foundation

The consulting services in mineral processes developed by MOPE have their theoretical foundation based on the OPERATIONAL MODEL, a process engineering compendium by the Chilean engineer Alexis P. Yovanovic, that has been developed in Brazil since 1987 for several operations with mineral particles transfer. It establishes an analogy with chemical processes creating a new phenomenological interpretation for the transfer between mineral particles. The Operational Model defines how the mineral particles would behave if they were molecules, always guiding them along the shortest path, just like the GPS for a driver.

The two Process Engineering books on the Operational Model are available for free download.

Engenharia da Cominuição e Moagem em Moinhos Tubulares (Engineering of Comminution and Grinding in Tubular Mills), ISBN 85904718-2-9. (2006)

Engenharia da Concentração e Massa por Flotação – Volume 1: Fundamentos da Flotação (Flotation Mass and Concentration Engineering – Volume 1: Fundamentals of Flotation), ISBN 85.904718-1-0. (2004)

Our Services

MOPECONTROL

A significant part of the mining segment is beginning to live with home office work. It will be much more effective with online support for plant monitoring, available to executives, process managers, and operators, those who like “seeing” the plant on their laptop screens at every moment and to know, remotely and in real-time, what is happening there. Properly supported for their decision-making processes, they can guide the field teams more effectively from anywhere the digital technology allows.

As a result of the development of several projects over the years, MOPE has developed procedures and strategies to support Operational Management and Process Engineering which, together with assisted operation and training, uses information available at the plant (manual/online) to bring control to the plant floor, stability to operation, and safety to the corporate environment.

MOPE’s consulting service culminates in a system totally customized to the plant’s reality. MOPECONTROL interfaces the available IT/TA modernity with the operation reality, using process concepts and simulations based on the OPERATIONAL MODEL to guide the continuous improvement in the plant, which makes it unique in the market. Acting in several levels of the company, MOPECONTROL brings the safety of having the plant in your hands.

Process Intelligence is the mature knowledge supported by the available technology!

During the MOPECONTROL implementation, MOPE counts with the specialized services of APTA Sistemas de Automação Ltda., an expert company in integration between Industrial Automation and IT, and also in verticalization of Industrial Systems. Therefore, we are ready to get the most out of the existing Automation and IT structures and, whenever needed, to deliver the relevant improvements.

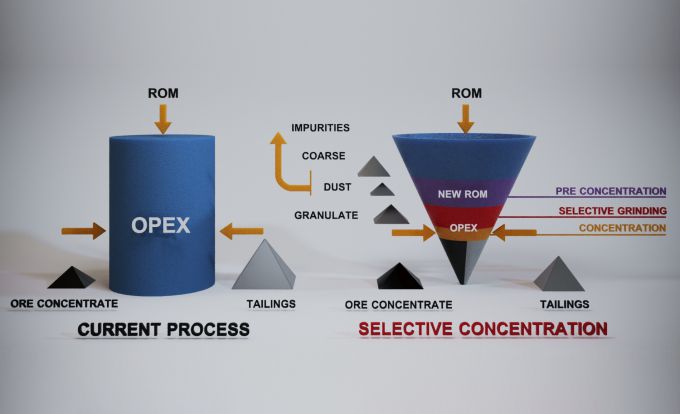

Selective Concentration

Currently, the ores are becoming increasingly poor and difficult to be processed. This is true both in new projects and in operative plants. By processing the poorest ore under the conventional way, greater volumes of resources are demanded: the consumption of energy, water, grinding media, reagents, etc., increases as the more gangue is treated, generating more and more amount of fine waste. CAPEX and OPEX are also increased.

MOPE has developed original SELECTIVE CONCENTRATION techniques that culminate in the best process route, both for new projects and optimization of operating plants.

There is, normally, a good ore inside the ROM, but it is necessary to discover it by discarding the excess of gangue as soon as possible and selectively enriching the flow (pre-concentration) before it reaches the most expensive operations of the plant. Still, the environment is grateful!

Plant Optimization

The fluctuating characteristics of the ores fed, the need for continuous, faultless operation, and permanent reduction of OPEX in operating plants, altogether compel companies to obtain answers and solutions to operational problems in shorter periods and smaller budgets.

MOPE understands these needs and, from a diagnosis specially made with our evaluation tools (MOPETOOLS) and our expertise in mineral processing, offers practical solutions, low cost, fast execution, and amazing results.

Conceptual Engineering

In its engineering projects, MOPE works in partnership with Oliveira Diniz, a company with over 25 years of experience in engineering solutions for small, medium, and large complex projects focused on the cement, mining, and steel industries.

MOPE always seeks the best solution within the current context, characterized by more complex and low content ores, water shortage, high energy costs, and environmental demands. We are responsibly creative.

Mining Engineering and Mining Services

In its package of services for the mineral market, MOPE counts on the support of partner companies with expertise in several areas. With a holistic view of the projects, the proposed solutions aim to guarantee the best cost-benefit for its customers.

Mining Proficiency Group is a MOPE partner company that provides cutting-edge solutions in Engineering and Services in the mining area, focusing on cost reduction, opportunity and risk analysis. The company is aligned with the best global practices of sustainable management, culminating in the best investment recommendations.