Copper – Caraíba shows the way

While CODELCO, a world copper giant, owned by the Chilean people, faces serious problems, the brave Caraíba mining company (Brazil, Bahia state) not only survives for more than 40 years of hard work, but also, after several innovations over time, lights the way-out for the big mining companies for dealing with the suffocation generated by both the sharp decrease in ore contents and the technical paralysis that arises from old paradigms.

Caraíba would have closed its operations more than 20 years ago if it had not been for the courage and sense of responsibility with the region where it is hosted: they brought out that type of creativity that emerges in the moments when the comfort zones are left. We would need a lot of time and paper to tell so extensive and full of success story as the one written by the Caraíba mining (it’s for another opportunity).

In this editorial we highlight that Caraíba has recently provided new elements which are in opposition to the main paradigm that keeps the major mining companies immobilized in the last 40 years. This paradigm is the belief that the rocks are normally homogeneous and generate fragments of identical content. Therefore, by not taking into account expectations of pre-concentration, large rocks could already be fed directly into the SAG (semi-automatic grinding) operation.

The controversial policy of grinding and floating all the material arriving from the mine has led CODELCO to a very worrying situation and it is not seen a way out of this problem, if the paradigm that keeps Chilean creativity dormant is not radically interrupted beforehand. That is why the concept discussed here is so important.

The solution presented

Caraíba had already carried out successful attempts in its Boa Esperança Project (Brazil, state of Pará). Another mining company in Pará has commented about its successful copper ore pre-concentration – before entering into the grinding process. After the right decision by the engineering team, the SAG mill has been removed from the process route at Serrote da Lage Project (Brazil, state of Alagoas) and the conventional grinding was started. The University of Sao Paulo (USP) is beginning researches about selective concentration in the crushing phase.

Brazil has shown itself to be more proactive in facing the decrease in ore grades, a common problem in mining worldwide, particularly in Chile, a country that nowadays constitutes a preferred market by large equipment suppliers due to the option to process all excess of gangue. CODELCO has followed this global path, which some Chilean executives call “proyectos en estándares internacionales” (Projects by international standards), that is, without taking into account the creativity required before the major Fortunately, Brazil early became aware of this problem, in a struggle in which MOPE has been directly involved since its beginning.

Fortunately, Brazil has early became aware of this problem, in a struggle in which MOPE has been directly involved since its beginning.

The new evidence

A few days ago we received the news announced to the public by ERO COPPER (owner of the Caraíba group), regarding to the pre-concentration works of several copper ores in the interior of Bahia state (Brazil).

Ero Copper announces excellent results from comprehensive ore sorting trial campaign

Naturally, it’s just a test and the “ore sorting” has some production scale limitations, despite the excellent results obtained. There is room to continue improving through the application of selective fragmentation techniques (MOPE) that maximize selectivity in the separation between gangue and mineral. In addition, consideration should be given to the removal of ultrafine dust, which brings many problems to the process.

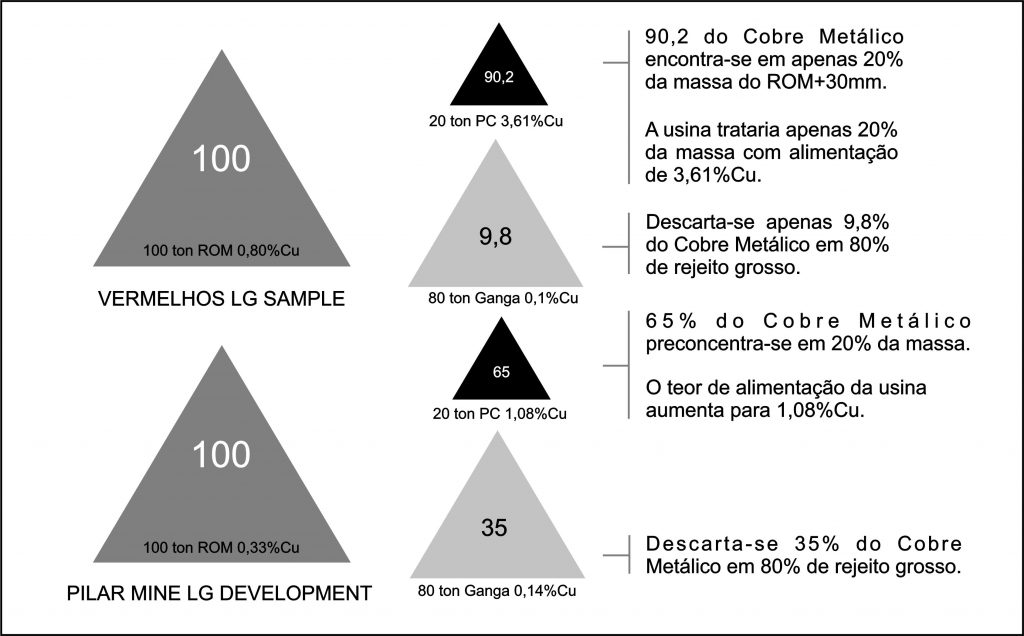

Data from the table found in the link highlighted above can be illustrated as shown in the figure below, taking as an example the poorest ores from the Vermelho deposit and as well the poorest ore from Pilar, considering material above 30 mm, which represents 70 to 85% average of all the ROM. Remembering that this is only the beginning of the beneficiation route, it is still missing to optimize the fragmentation and then the selective grinding, which would allow discarding more granulated gangue from the circuit. The pre-concentrate reduces the mass to 20% and increases the content.

Even in the experimental phase (there is room for improvement) the tendency is to discard a huge amount of gangue already in the initial phase of the process, as estimated in the special cases of the example above – each ore can generate a different result. The plant would be much smaller, especially in the grinding operations, the most expensive one in a Concentrator.

From MOPE’s experience, we consider that, depending on the selectivity in the fragmentation and pre-concentration, the cut-off grade in the mine could be reduced, making better use of the reserves.

Once again, it is noted that the best solutions arise from a conceptual restructuring in mining, based on sound sense and experience. Caraíba has plenty of it, with a branch directed by an experienced colleague that counts also with a qualified technical team.

Alexis Yovanovic