The Man and the Technology in Concentrating Plants

The importance of the workers in the integration and implementation process of the new technologies available for the mining sector was one among the aspects highlighted by the panelists of the webinar “Transformación digital del capital humano para la minería 4.0” (see below the link in Spanish).

Delia Lazarte (Tribe Leader Productos from Entel Corporaciones) explained that the technology itself doesn’t add value, unless there is the human capital to take advantage of it.

There is technology that merely replaces the human capital, another one that frees (or protects) it from dangerous situations. There is also the “adjustment” technology. It is, perhaps, the most frequent one, which dehumanizes our daily lives, and gradually pushes us to adapt ourselves to the digital world we are obliged to live in. Should the human being adapt himself to take advantage of technology? Whatever technology?

The “specialized technology” nowadays make it possible to pilot a robot, from hundreds of kilometers away, to lift a rock, or allows conducting giant trucks without a driver, thus reducing the action of the human being. Naturally, there are people who see this type of technology as a threat, as they may lose their jobs.

In the concentrating plants, this “modernity”, when it arrives top down, hides what it does not know, dressed as “universal technology” with multipurpose software, so generic that, in thesis, it would serve for dozens of different industrial activities. When some modernity tries to “operate” a process automatically, it closes it in a black box and sets a system identification procedure, valid for any “system” where one can relate “inputs to outputs”. However, the enchantment for these types of simulators has been lasting a short time in concentrators.

The point raised here is that, in the concentrators, it is the technology (and who develops it) that must be humble enough to recognize its lack of knowledge and to be next to the operator making itself available. Technology will unlikely reduce employees in a concentrator, even if it wanted to once it does not know “the field” deep enough. Nevertheless, it could help the operator so that, together they can face the real challenges of the plant: to increase production and to reduce inputs and services.

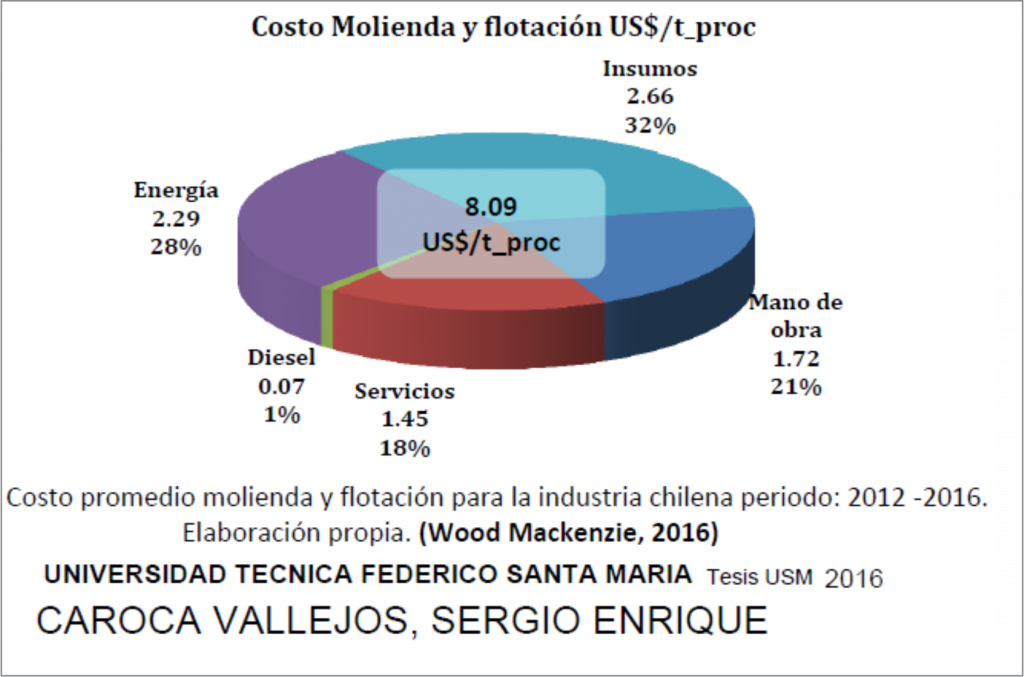

In a typical copper mining concentrating plant for example (see figure below – Fundación Chile, Roadmap Tecnológico para 2015-2035), almost 65% of the cost is allocated to comminution and flotation operations.

For their side, grinding and flotation costs show that only 21% of them are labor costs. The technology should not be thought primarily to go further reducing manpower, but should help operators to increase production (and reduce unitary cost) and also to combat the other 79% operating costs.

Unfortunately, with this strong globalization, we do not always distinguish who develops generic technology to hide what they do not master; who does it to sell more inputs (balls, reagents, replacement screens, wear parts, etc.) and services or who develops technology to help the operator reduce the first ones.

Alexis Yovanovic

Ante la transformación tecnológica de la minería, el capital humano será clave

La importancia de los trabajadores en el proceso de integración y puesta en marcha de las nuevas tecnologías disponibles para el sector minero, fue uno de los aspectos destacados por los expositores del webinar “Transformación digital del capital humano para la minería 4.0”, que fue organizado por el Programa Estratégico Regional Clúster Minero de Corfo Antofagasta. En esta ocasión, la jornada, que formó parte del ciclo de webinars “Minería con visión de futuro”, abordó la manera en que los trabajadores están siendo parte relevante del proceso de digitalización que está experimentando el sector minero.

Fuente: Minería Chilena