DRY CONCENTRATION – No “secrets”

The need or convenience of Dry Concentration arises naturally in arid places and with resistance from the local environment, but it also appearing from the mineralogical composition of the mineral, where the size and specific gravity of the grains that make up a particle , which arise from a correct fragmentation (selective fragmentation – MOPE) offer conditions for this.

At a time when technology manufacturers are working to register a “patent” on the matter, it is important to remember that “prompt machinery” and closed panels are not required, as none of this is necessary to attempt a dry concentration route for any mineral, provided there is conviction, courage and conceptual creativity to do it, even partially.

MOPE studies dry routes for various types of ore in alliance with laboratories in Chile and Brazil. For Copper, Gold and other minerals, the dry concentration normally reaches the fine crushing stage (selective fragmentation) and harneo, with discarding of gangue and dust, preconcentrating the flow of ore that continues forward. In other cases, such as the iron ore, it is possible to get to the final concentrate.

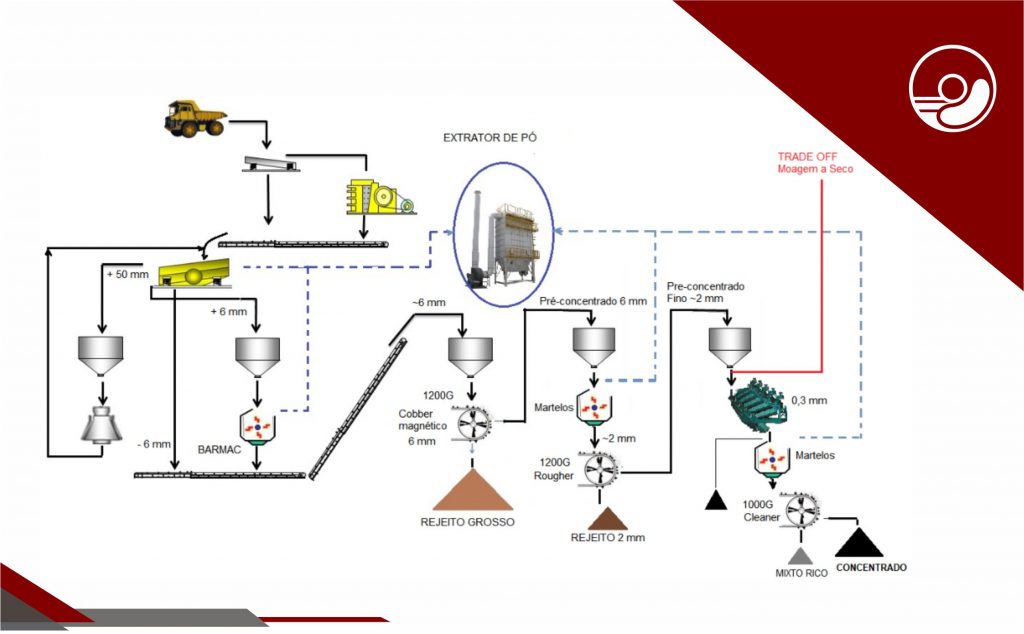

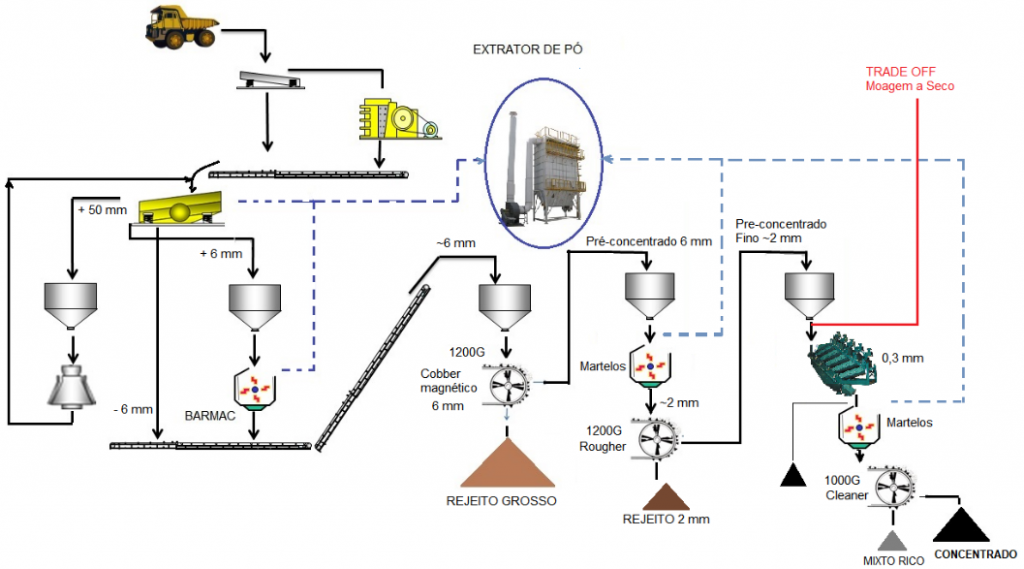

It all starts with adequate dry fragmentation (selective), better separating the grains and allowing the timely disposal of gangue and dust. Dust is normally a “poison” to the process, in several ways. Below is ilustrated a typical process route that MOPE uses for Magnetite.

The great secret of dry concentration is in what the mineral itself has to count, where each case is a case. Anyone can test and project the route illustrated above, even though MOPE help may add value. In addition to its recognized passion and professional conviction in favor of what it believes, MOPE has defined experimental procedures, has its own calculation tools and technical competence. Do you want to study Dry Concentration together with us?

Alexis Yovanovic